VEL/VCL serial mobile suction cup lifter with stacker

1. Max.SWL 300KG

Low pressure warning.

Adjustable suction cup.

Remote control.

CE certification EN13155:2003.

China Explosion-proof Standard GB3836-2010.

Designed according to German UVV18 standard.

2. Easy to customize

Thanks to a large range of standardized grippers and accessories, such as swivels, angle joints and quick connections, the lifter is easily adapted to your exact needs.

3. Ergonomic handle

The lifting and lowering function is regulated with an ergonomically designed control handle. Controls on the operating handle make it easy to adjust the lifter's stand-by height with or without a load.

4. Energy-saving and fail-safe

The lifter is designed to ensure minimum leakage, which means both safe handling and low energy consumption.

+ For ergonomic lifting up to 300 kg.

+ Rotate in horizontal 360 degrees.

+ Swing angle 270.

| Serial No. | VEL120-2.5-STD | Max capacity | Horizontal suction of dense workpiece 50kg; Breathable workpiece 30-40kg |

| Overall Dimension | 1610*1360*1020mm | Own Weight kg | 520KG |

| Power supply | 380VAC±15% | Power input | 50Hz ±1Hz |

| Control mode | Manually operate the control handle to suck and place the workpiece | Workpiece displacement range | Minimum ground clearance100mm, Highest ground clearance1600mm |

| Vacuum created equipment | Vacuum blower | Vacuum equipment | Length of Jib arm2500mmHeight of column: 2900mm |

| Type | VEL100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

| Capacity (kg) | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

| Tube Length (mm) | 2500/4000 | ||||||||

| Tube Diameter (mm) | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

| Lift Speed(m/s) | Appr 1m/s | ||||||||

| Lift Height(mm) | 1800/2500 | 1700/2400 | 1500/2200 | ||||||

| Pump | 3Kw/4Kw | 4Kw/5.5Kw | |||||||

| Type | VCL50 | VCL80 | VCL100 | VCL120 | VCL140 |

| Capacity (kg) | 12 | 20 | 35 | 50 | 65 |

| Tube Diameter (mm) | 50 | 80 | 100 | 120 | 140 |

| Stroke (mm) | 1550 | 1550 | 1550 | 1550 | 1550 |

| Speed(m/s) | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 |

| Power KW | 0.9 | 1.5 | 1.5 | 2.2 | 2.2 |

| Motor Speed r/min | 1420 | 1420 | 1420 | 1420 | 1420 |

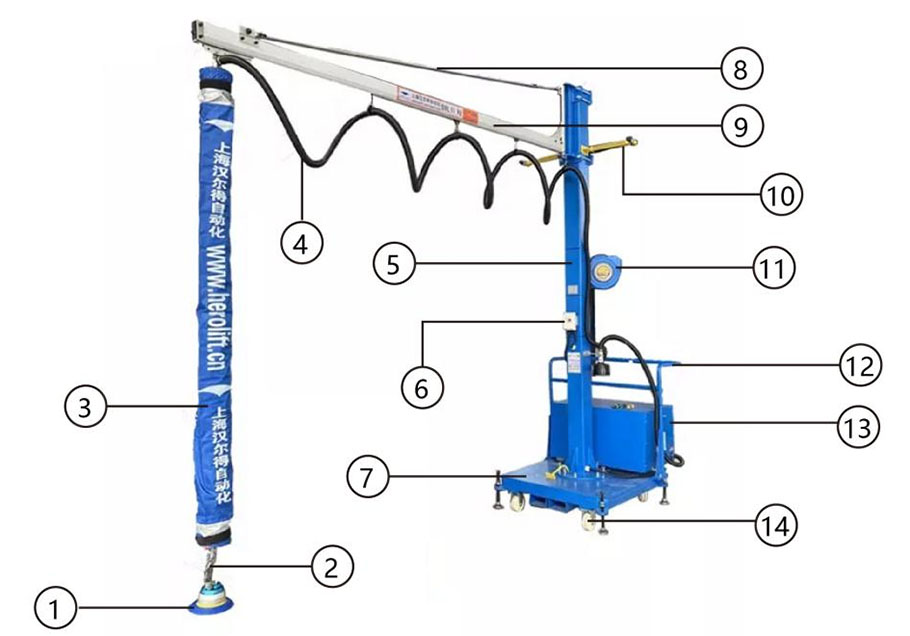

| 1. Suction Foot | 8. Jib Rail Brace |

| 2. Control Handle | 9. Rail |

| 3. Load tube | 10. Rail stopper |

| 4. Air tube | 11. Cable reel |

| 5. Steel Column | 12. Push Handle |

| 6. Electrical control box | 13. Silence box( For optional) |

| 7. Steel movable base | 14. Wheel |

● User friendly

vacuum tube lifter use suction to both grip and lift the load in a single movement. The control handle is easy for the operator to use and feels almost weightless. With a bottom swivel, or an angle adaptor, the user can rotate or turn the lifted object as required.

● Good ergonomics means good economics

Long lasting and safe, our solutions provide many benefits including reduced sick leave, lower staff turnover and better staff utilization — usually combined with higher productivity.

● Unique personal safety

Herolift product designed with several built-in safety features. For example, our non-return valve a standard on all units ensures that the load is not dropped if the vacuum suddenly stopped running. Instead, the load will be lowered to the ground in a controlled manner.

● Productivity

Herolift not only makes life easier for the user; several studies also show increased productivity. This is because the products are developed using the latest technology in cooperation with industry and end-users' demands.

● Application specific solutions

For maximum flexibility the tube lifters are based on a modular system. For instance, the lift tube can be changed depending on the lifting capacity required. It is also possible to have an extended handle fitted for applications where extra reach is required.

For sacks, for cardboard boxes, for wooden sheets, for sheet metal, for drums, for electrical appliances, for cans, for baled waste, glass plate, baggage, for plastic sheets, for wood slabs, for coils, for doors, battery, for stone.