Vacuum lifting device materials handling stacker mobile vacuum tube lifter for Paint industry

The versatility of the vacuum lifter is a major highlight of its capabilities. It can be easily moved to multiple workstations allowing for various work areas within the facility. This flexibility enables seamless operation and ensures products meet the unique requirements of different industries and environments.

The mobile vacuum tube lifter features cutting-edge technology utilizing vacuum suction cups and a powerful drive system. This combination makes it easy to lift, move and rotate material without heavy lifting or repetitive moving by hand. By using vacuum suction cups, this type of transport can firmly grip the material, preventing any potential accidents or shifting during transport. A powerful drive system ensures the transporter can handle heavy loads without compromising efficiency or safety.

CE certification EN13155:2003

China Explosion-proof Standard GB3836-2010

Designed according to German UVV18 standard

Lifting capacity: <270 kg

Lifting speed: 0-1 m/s

Handles: standard / one-hand / flex / extended

Tools: wide selection of tools for various loads

Flexibility: 360-degree rotation

Swing angle240 degrees

A large range of standardized grippers and accessories, such as swivels, angle joints and quick connections, the lifter is easily adapted to your exact needs.

2,24VDC rechargeable mobile handling suction crane

It can take into account the handling of different stations, mainly used for warehouseWarehouse material transfer.

3,Scissor-type folding arm,

Arm extension 0-2500mm, retractable pendulum.Move freely and save volume. (with self-locking mechanism)

4,AC and DC power switching for different application needs seek

Battery endurance test: the stacker car is still work. Sucker load automatic lifting and lowering test:

Test results: After full charging, the suction crane continues. After running for 4 hours, the remaining battery power is 35%. Power off for charging.The longer the battery life, the longer the absorption,the longer the crane works。

For sacks, for cardboard boxes,for wooden sheets, for sheet metal,for drums,

for electrical appliances, for cans, for baled waste, glass plate, baggage,

for plastic sheets, for wood slabs, for coils, for doors, battery, for stone.

| Type | VEL100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

| Capacity(kg) | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

| Tube Length(mm) | 2500/4000 | ||||||||

| Tube Diameter(mm) | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

| Lift Speed(m/s) | Appr 1m/s | ||||||||

| Lift Height(mm) | 1800/2500

|

1700/2400 | 1500/2200 | ||||||

| Pump | 3Kw/4Kw | 4Kw/5.5Kw | |||||||

| Type | VCL50 | VCL80 | VCL100 | VCL120 | VCL140 |

| Capacity(kg) | 12 | 20 | 35 | 50 | 65 |

| Tube Diameter(mm) | 50 | 80 | 100 | 120 | 140 |

| Stroke(mm) | 1550 | 1550 | 1550 | 1550 | 1550 |

| Speed(m/s) | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 |

| Power KW | 0.9 | 1.5 | 1.5 | 2.2 | 2.2 |

| Motor Speed r/min | 1420 | 1420 | 1420 | 1420 | 1420 |

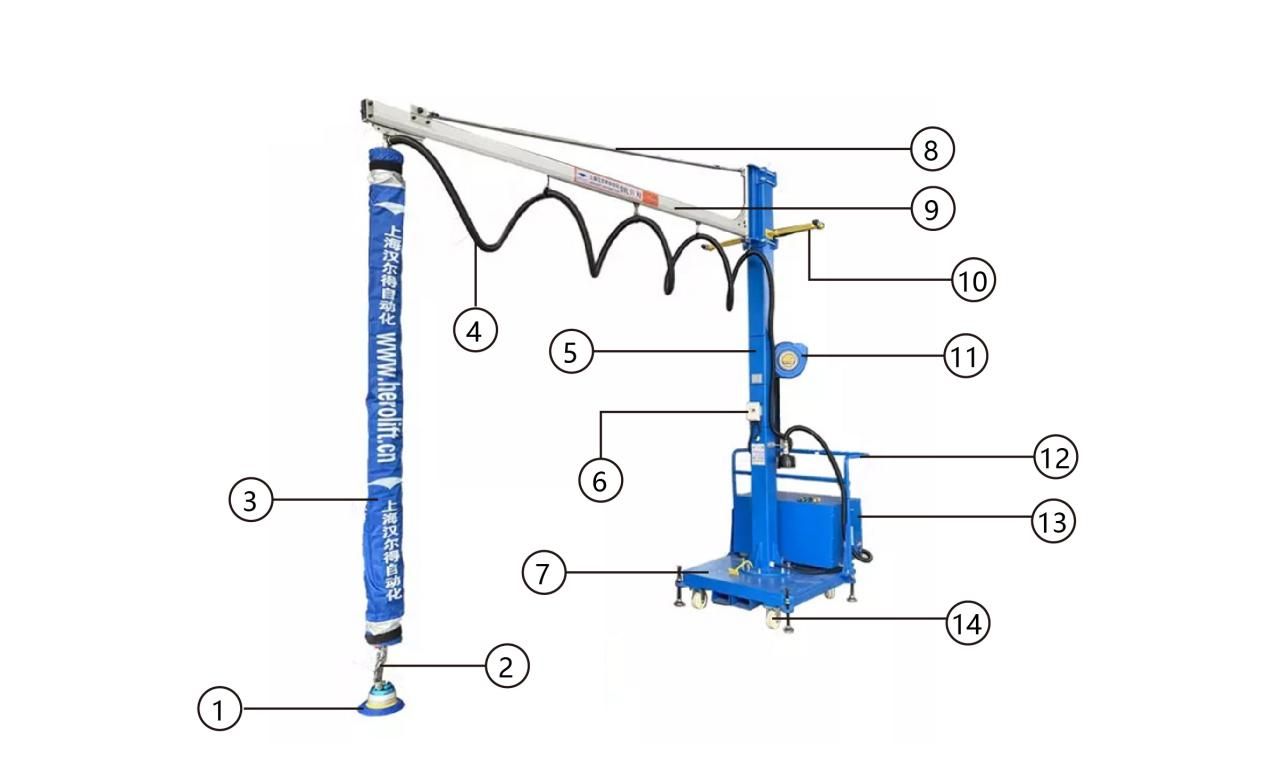

| 1,Suction Foot | 8, Jib Rail Brace |

| 2,Control Handle | 9, Rail |

| 3,Load tube | 10,Rail stopper |

| 4,Air tube | 11,Cable reel |

| 5,Steel Column | 12,Push Handle |

| 6,Electrical control box | 13,Silence box( For optional) |

| 7,Steel movable base | 14,Wheel |

Suction foot assembly

•Easy replace •Rotate pad head

•Standard handle and flexible handle are optional

•Protect workpiece surface

Jib arm stopper

•Achieve 0-270 degrees rotate or stop.

Air hose

•Connecting blower to vacuum suction pad

•Air hose connection

•High pressure corrosion resistance

•Provide security

Crane Systems and Jib Cranes

•Consistently light weight design

• Saves more than 60 percent of the force

• Stand-alone solution-modular system

• Material optional,Scheme customization

Wheel

•High quality and robust wheel

•Good durability, low compressibility

•Esay access to controls and brake function

Silence hood

•Design according to performance requirements

•Wave sound-absorbing cotton Effectively reducing noise

•Customizable exterior painting

Since its establishment in 2006, our company has served more than 60 industries, exported to more than 60 countries, and established a reliable brand for more than 17 years.